These are the most commonly used fixed fire extinguishers. This category includes sprinkler and flood systems. The heads of the sprinkler system are equipped with a heat-sensitive fuse, so that the water is sprayed only where the temperature rises and the fuse blows. They can be used in offices, department stores, industrial halls and warehouses.

The flood system heads are open. In case of activation, water is sprayed from all heads in the given section. Flood systems are used to protect against rapidly spreading fires or as a replacement for fire dividing structures.

Wet sprinkler system

The wet pipe system is the simplest and most widely used fire sprinkler system. Wet systems are frequently installed in factories...

Dry sprinkler system

Dry pipe system are most frequently installed in areas subject to freezing temperatures, such as unheated storage areas...

Preaction system

This system provides increased security against accidental release of false alarm of sprinkler system and influence...

Deluge sprinkler system

This system ensures rapid and complete flooding of the space with water, with high fire risk, such as aircraft hangers...

Wet pipe system

The wet pipe system is the simplest and most widely used fire sprinkler system. Wet systems are frequently installed in factories warehouses and Office buildings where the risk of freezing ambient temperatures is negligible.

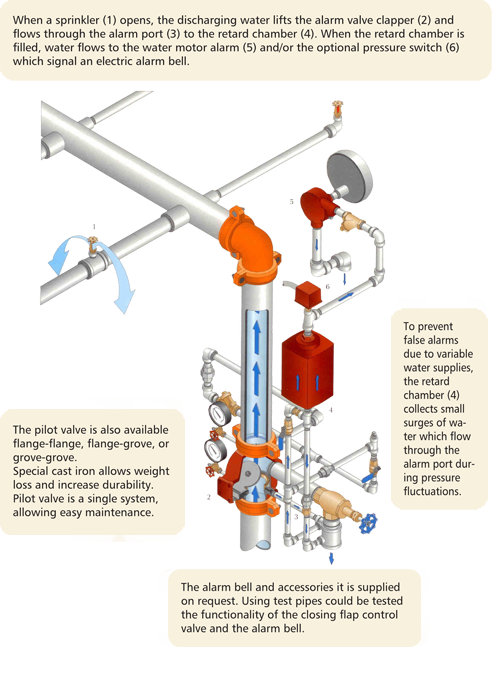

When a sprinkler (1) opens, the discharging water lifts the alarm valve clapper (2) and flows through the alarm port (3) to the retard chamber (4). When the retard chamber is filled, water flows to the water motor alarm (5) and/or the optional pressure switch (6) which signal an electric alarm bell.

To prevent false alarm due to variable water supplies, the retard chamber (4) collects small surges of water which flow through the alarm port during pressure fluctuations.

The pilot valve can be supplied in flange-flange, flange-grooved connection, or grooved-grooved connection. The special cast iron made it possible to reduce the weight and increase the service life.

The entire control valve is a single system, which allows for easy maintenance.

Dry pipe system

It is applied to environments endangered by frost, e.g. unheated storage areas, loading areas, underground garages, etc. Instead of water, the system is filled with compressed air and floods only in the event of a fire.

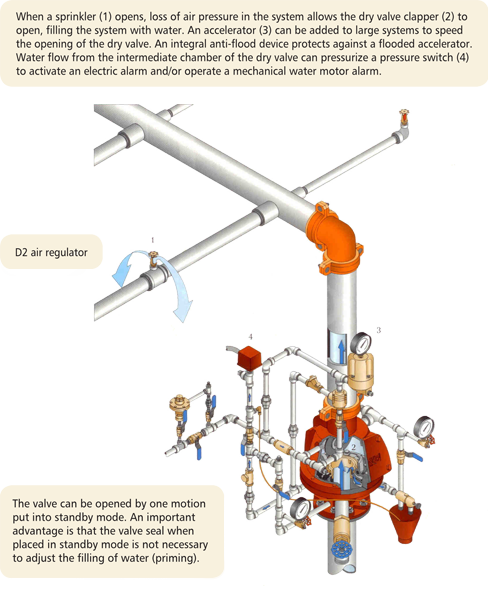

When any sprinkler (1) is opened in a dry system, the air pressure in the duct drops. As a result of the pressure balance, the dry valve flap (2) opens and the piping system is filled with water. In a large piping system, the accelerator (3) will ensure faster air discharge and flooding of the system. The overflow water activates the alarm pressure switch (4) and the alarm bell.

Once opened, the valve can be moved to the standby position in one movement. A significant advantage is that the valve seal does not need to be primed when water is brought into the standby position.

Preaction system

This system provides increased safety against accidental start-up of the sprinkler system due to a false alarm. Compared to a dry system, the advance system significantly shortens the time between the occurrence of a fire and the spray of water. It is used to protect laboratories, libraries and depositories.

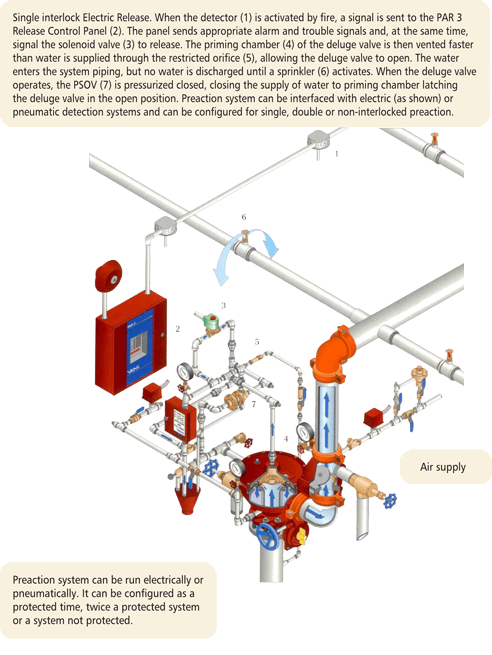

Once secured preaction system – in case of fire, the detector (1) is activated, the signal is transfered to the control panel (2). The control panel commands the acoustic signaling and at the same time the solenoid valve (3) opens. The piping filling the main chamber (4) with water cannot compensate for the pressure drop in the main chamber, which makes it possible to open the flood valve.

Water enters the piping system, but no water is sprayed unless the sprinkler (6) bursts.

The preaction system can be started electrically or pneumatically. It can be configured as a once protected, twice protected system, or a system without protection.

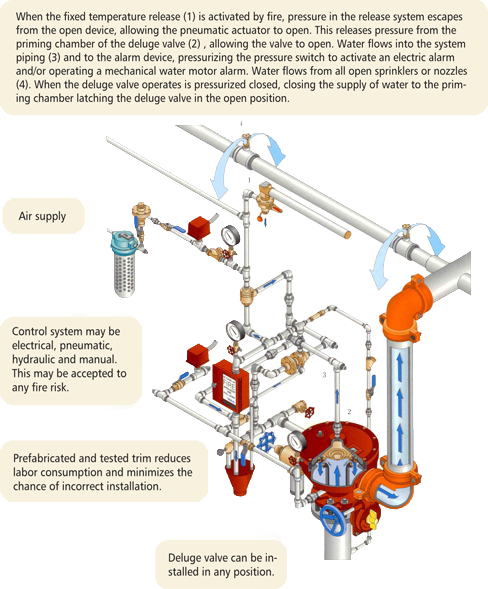

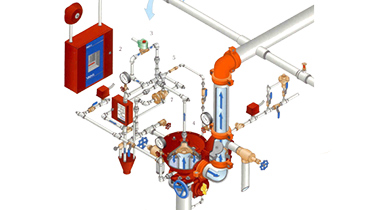

Deluge system

This system ensures rapid and complete flooding of the space with water, with high fire risk, such as aircraft hangers, power plants, generating stations and petrochemical facilities. On the basis of fire risk can be used for manual, pneumatic, hydraulic, or electric starting system.

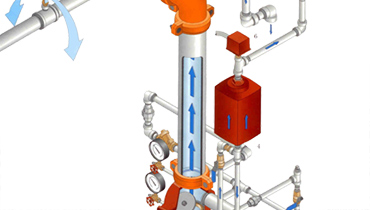

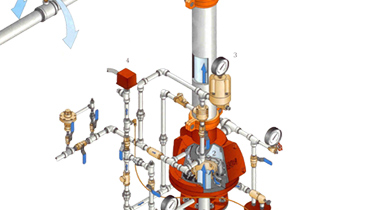

When the detector (1) detects a fire, a pressure drop occurs in the hydraulically or pneumatically actuated system. As a result, there is a loss of pressure in the upper chamber of the Deluge valve (2), the valve diaphragm opens and water begins to flow to the heads. Smoke or fire detectors can also control the Deluge valve.

The pressure-controlled valve (3) further regulates the pressure drop, so that the Deluge valve is kept in the open position, it is not able to bring itself to the standby position by itself. Water flows through the open heads (4).

The control system can be electric, pneumatic, hydraulic and manual. This makes it possible to meet any fire risk.

The deluge valve can be installed in any position.